SEALING PROFILES

Learn more about Industrilas extensive range

of sealing profiles for many different needs and applications.

Steel and wire carrier in sealing profiles

Our sealing profiles and edge protections have a core (called "carrier") of metal to improve the grip on the material the product is attached to. The carrier may be on of three kinds:

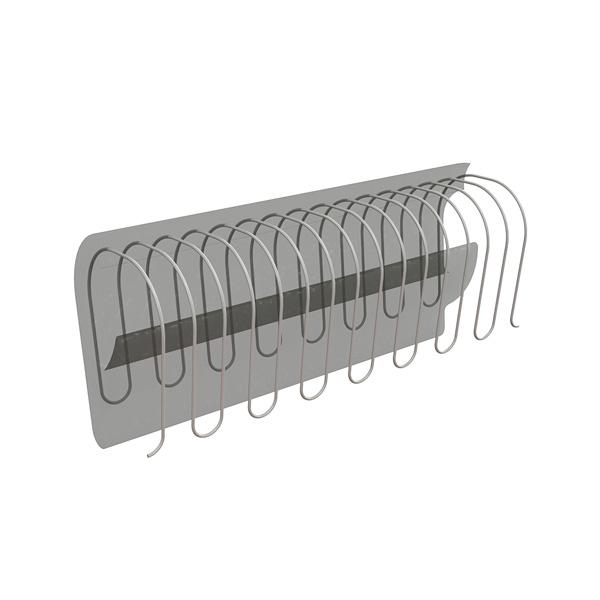

Wire carrier

This type of carrier is a thin wire moulded into the profile. This results in a in a profile that is soft and is relatively easy to bend in all directions. The grip (clamping effect) is softer than the next two options.

Steel carrier - unbroken

Here, a thin, unbroken, metal strip is moulded into the profile resulting in a better grip (clamping effect) when the profile is attached to the door. The steel carrier makes the profile less flexible, and is more suitable for straight applications or curves with a large radius.

Steel carrier - broken

In this version, the thin metal strip is moulded into the sealing profile, but it is broken up in many small parts - resembling a long row of small metal clips. The result is a profile with a good grip - and with a better flexibility than with a solid carrier. In this application, the profile may result in a slightly uneven strand over time. This version should be used if you need a profile with a good grip and if it will be used in an application with curved areas.

The choice of either a steel or wire carrier largely depends on the application and the desired appearance. Therefore, practical tests are required in your particular application.

Profile with wire carrier results in a soft, relatively flexible and pliable profile with increased gripping force thanks to the "springy" nature of the wire, holding the edge.

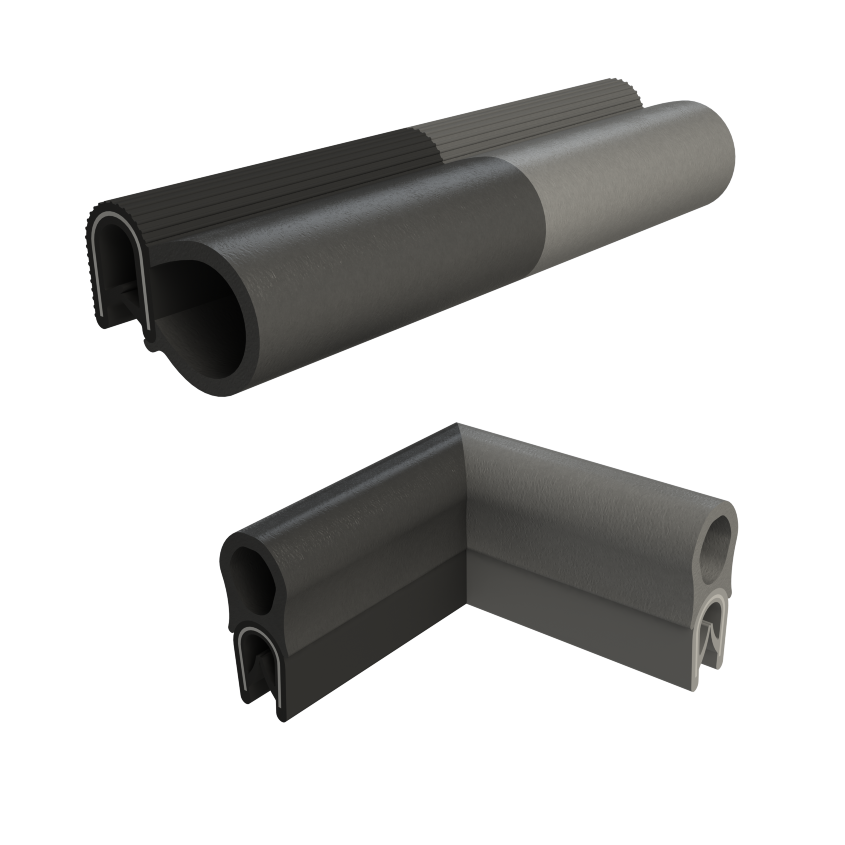

Profile with metal carrier unbroken (top) as a great grip on straight materials but is difficult to bend in curved areas as all clips are connected and made from one piece of metal. A profile with broken carrier (bottom) is easier to bend around curves as the clamps are "separated".

To assist you, we have in many cases included the estimated bending radius values for the profiles in question. These values are only an approximation based on practical tests and should serve as guidelines for you. The profiles can also be installed in narrower radii, but then the hose or the lip will deform significantly.

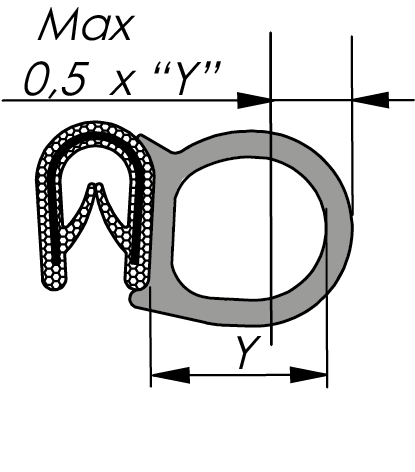

Compression for sealing edge protection profiles

The compression of our sealing edge protection profiles should be at maximum 50% of the "bubble". In practice, the profile should be compressed 30-40% in order to creating the best possible tension in the "bubble", for the best seal possible.

Maximum recommended amount of compression of the sealing profile "bubble" for optimum sealing function.

Custom sealing profiles & edge protection profiles

On request we can vulcanize, glue and weld rubber profiles to create shapes like circles and ovals (image A) or rectangles and corners (image B). This, however, is only economically feasible in larger quantities.

We can also supply you with profiles in pre-cut lengths of your choice. We can also supply you with sealing profiles with these functions:

Low-friction coating ("slip-coat")

Simplifies opening/closing and prevents the door sticking to the seal in sub-zero applications.

Butyl-filled profiles

For increased protection against water leakage and increased adhesion (grip) on the edges. Butyl is non-hardening and elastic and creates an excellent seal under harsh conditions.

Fire proof and flame proof profiles.

#### SKRIVA LITE BESKRIVANDE TEXT HÄR ####

Hygiene profiles

For applications when manufacturing food, pharmaceuticals, biotechnics, cosmetics and similar. Manufactured according to VDI 6022.

If you do not find the profile you need within our standard range, please contact us for custom solutions.

Generally speaking it is always possible to alter the grip range of a specific profile or edge protector without the need for retooling expenses. Please contact us and specify the material thickness which the profile needs to grip, and we will help you.

For material information, please refer to the table below.

Properties of rubber

| Material | Natural rubber | Styrene butadiene rubber | Nitrile rubber (Perbunan™) |

Chloroprene rubber (Neoprene™) |

Ethylene propylene-diene rubber (EPDM™) |

Fluorine rubber (Viton™) |

Methyl silicone rubber (Silopren™) |

Polyvinyl chloride (Vestalit™, Vestolit™) |

|---|---|---|---|---|---|---|---|---|

| Abbreviations according to ASTM D 1418 | NR | SBR | NBR | CR | EPDM | FKM | MQ/MVQ | PVC |

| Hardening (Shore A) (±5) | 40-90 | 45-90 | 45-90 | 40-90 | 40-90 | 65-90 | 30-80 | 55-95 |

| Resistance to tearing (N/mm2) (B) | 4-15 | 4-15 | 4-14 | 4-15 | 6-13 | 0 | 0 | 0 |

| Spring-back elasticity at 20°C | ++ | + | 0 | + | + | 0 | 0 | |

| Abrasion resistance (B) | ++ | ++ | + | + | + | 0 | 0 | 0 |

| Chemical resistance (A) | + | + | 0 | + | ++ | ++ | + | ++ |

| Oil resistance (A) | - | - | ++ | + | - | ++ | + | + |

| Fuel resistance (A) | none | - | + | - | - | ++ | - | - |

| Solvent resistance (A) | - | - | + | + | 0 | 0 | + | 0 |

| Temperature resistance in °C (C) | -40 to +80 | -30 to +80 | -30 to +100 | -25 to +100 | -40 to +120 | -20 to +200 | -50 to +180 | -25 to +60 |

| Ozone resistance | 0 | 0 | 0 | ++ | ++ | ++ | ++ | 0 |

| Weather exposure resistance | + | + | + | ++ | ++ | ++ | ++ | + |

| Gas penetration resistance | 0 | 0 | + | + | 0 | 0 | + | |

| Resistance to permanent deformation (B) | ++ | + | + | + | + | 0 | 0 | 0 |

| Binding to metal | ++ | ++ | 0 | + | 0 | 0 | 0 | |

| Dielectric qualities | ++ | + | - | 0 | ++ | + | + | 0 |

(A)

Due to the great number of existing chemicals, possible temperatures and times of exposure, the stated qualities can vary from case to case.

(B)

The qualities of the rubber become worse at relatively high or low temperatures.

(C)

The stated ranges are accurate under normal circumstances. Extreme strains or environments will make the actual ranges smaller.

++ = Perfect or very good.

+ = Good.

0 = Average qualities.

- = Poor qualities.

Protective EMI/RFI-film for sealing profiles

Many of Industrilas' sealing profiles can be equipped, fully or in part, with a film protecting against EMI (Electromagnetic Interference) and RFI (Radio Frequency Interference).

Many of Industrilas' sealing profiles can be equipped, fully or in part, with a film protecting against EMI (Electromagnetic Interference) and RFI (Radio Frequency Interference).

Please refer to the table below for detailed information obout the film.

EMI/RFI-film data

| EMI-coating | Copper/Tin-coated non-woven (Cu/Sn-PBN-II) |

|---|---|

| Dampening | Average of 90dB from 30 MHz to 1 GHz |

| Abrasion resistance | 1,000,000 cycles |

| Temperature range | -30°C to 90°C |

| Film thickness | 0,25 mm - 0,40 mm |

| Colour | Black |

| Type of adhesive | Acrylic bas |